Glassy carbon, is a kind of pure carbon material, which combines the performance of glass and ceramic together with graphite. While, different with Graphite, the glassy carbon is with the structure just like that for Fullerene, which makes it with it`s own performances. Glassy carbon can be machined to glassy carbon rod, plate and tube, as well as different shapes of glassy carbon crucibles.

♦Resistance against all wet decomposition agents,

♦No memory effects (uncontrolled adsorption and desorption of elements),

♦No contamination of the analytical sample,

♦Resistance against acid and alkaline melts,

♦Non-porous, glassy surface,

♦Main products include crucibles, beakers, boats and dishes for fuming-off, evaporating, melting and decomposition etc.

♦High thermal conductivity

♦Much longer service time than graphite crucibles

♦No adhesion of noble metal melts

♦Resistance to thermal shock

♦Suitability for all noble metal and titanium alloys

♦Use in induction-heated casting centrifuges

♦Generates a protective atmosphere over the metal melt

♦No melting salt required

Melting vessels of show a demolding with a very high surface quality, no contamination by foreign elements and due to the hardness and wear resistance no carbon traces in the melting substance. Metal melts which do not form carbides have no wetting effect. Its good thermal shock resistance allows rapid heating and cooling times and red-hot crucibles do not crack when placed on cold surfaces.

High temperature resistance in inert gas or vacuum up to 3000°C

Glassy carbon SIGRADUR® is high temperature resistant in inert gas or vacuum up to 3000°C. Unlike all other ceramic and metallic high temperature materials, glassy carbon increase in strength with a rise in temperature up to 2700 K. Glassy carbon shows at 2700 K compared to room temperature the double strength. Compared to ceramic and metallic materials, glassy carbon shows even at high temperatures no embrittlement.

High purity

Glassy carbon is made of pure carbon. The other materials besides carbon in it are extremely low in content, when heated over 2000°C, At these high temperatures the most foreign elements vaporize and only pure carbon remains. Due to the high purity glassy carbon is suitable for applications in the chemical analysis, semiconductor technology and ultra pure materials technology. Glassy carbon shows no memory effects which is advantageous in the ultratrace analysis.

Extreme corrosion resistance

Glassy carbon has an extreme corrosion resistance. Due to the closed microstructure glassy carbon doesn't form intercalation compounds. This gives extremely high resistance to corrosion by acid and alkaline agents and melts. Strong oxidizing substances like oxygen over 600°C and hot melts and acids with a powerful oxidizing action are the only substances to attack glassy carbon. But even here tests showed that glassy carbon is the most oxidation resistant carbon material.

Due to the high purity the catalytic action of foreign elements (reaction centres) concerning oxidation and corrosion is limited to a minimum. Glassy carbon shows a higher corrosion resistance to oxidizing substances like nitric acid, perchloric acid or oxygen. The oxidation speed of glassy carbon in boiling 65% nitric acid is 24 fold lower than glassy carbon.

Impermeability to gas and liquid, no open porosity

Glassy carbon is an impermeable material comparable with silica glass. The helium permeability as determined by the vacuum drop method is only 10-11 cm2 s-1. Thus glassy carbon is an ideal material for the vacuum technology.

No wetting by melts

Glassy carbon shows no wetting by many saline, metallic and ceramic melts. This is advantageous in the metallurgy, ultra pure materials technology and glass industry.

High hardness and strength

The mechanical properties of glassy carbon, like hardness and strength, are comparable with these of high-performance ceramics. Unlike all other ceramic and metallic high temperature materials, glassy carbon increase in strength with a rise in temperature up to 2700 K. Glassy carbon shows at 2700 K compared to room temperature the double strength.

Low density

Glassy carbon has despite the high strength a very low density. E.g. charging equipment made of glassy carbon has due to the low mass a very low thermal absorption which enables short heating and cooling times. Also for light weight constructions and high dynamic stressed units glassy carbon is used due to its low density.

High surface quality, no particle generation

Glassy carbon has a very high surface quality and can be polished. Due to the hard and smooth surface glassy carbon doesn't show any particle generation like other carbon materials. Therefore it is very suitable for the semiconductor and glass industry.

Low thermal expansion

Glassy carbon has a very low and isotropic thermal expansion comparable with silica glass. Therefore it retains its shape under heat which is very advantageous for all high temperature applications.

Extreme resistance to thermal shock

In comparison to the most ceramic and metallic materials glassy carbon has an extremely high resistance to thermal shock. Therefore short heating and cooling times are possible without any problems.

Isotropy of physical and chemical properties

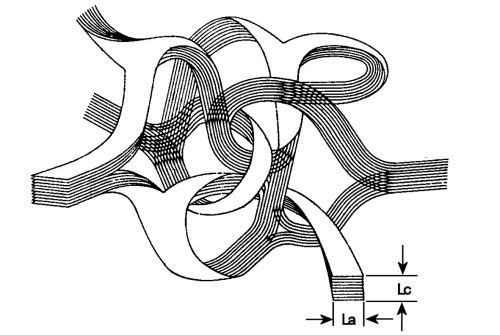

Glassy carbon is an isotropic material. Due to its fullerene-related microstructure glassy carbon has no directional material properties.

Good electrical conductivity

Glassy carbon is electrical conductive and thus suitable for e.g. the electrochemistry and sensor technology. Melting crucibles can be heated inductively.

Biocompatibility

Glassy carbon is resistant against biological systems and shows an excellent compatibility with blood and tissue. Good mechanical properties at low density, high purity and biocompatibility make glassy carbon SIGRADUR® to an interesting material for medical technology and biotechnology.